Wholesale Dealers of Screw Press Palm Oil Mill - Screw Press sludge dewatering machine – Haibar

Wholesale Dealers of Screw Press Palm Oil Mill - Screw Press sludge dewatering machine – Haibar Detail:

Mechanical Principle

The initial section of dewatering drum is Thickening Zone where the solids-liquid separating process takes place and where the filtrate will be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, increasing the internal pressure of the drum. At the end, End Plate further increases the pressure so as to discharge dry sludge cake.

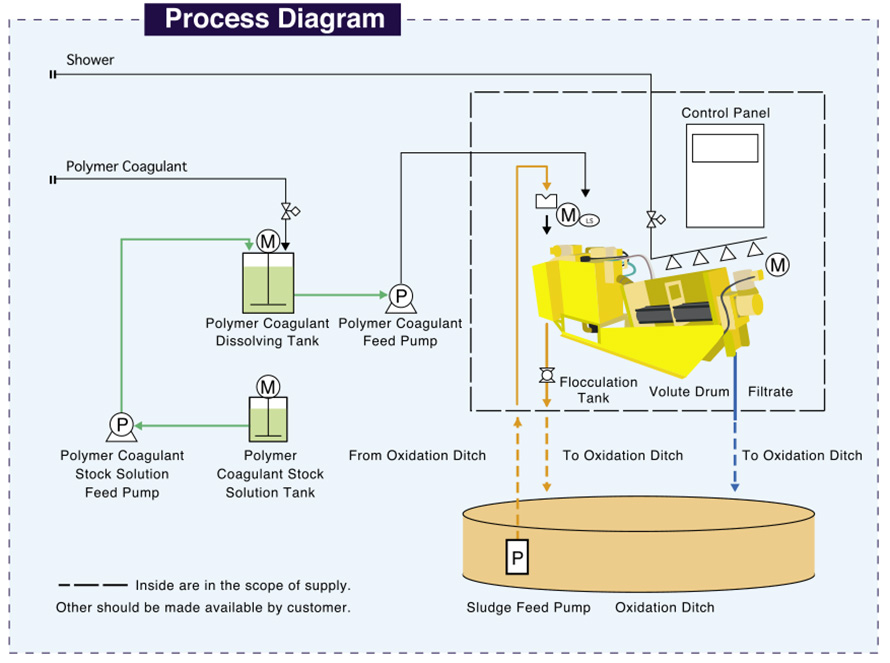

Process Diagram of the Vloute Dewatering Press

Sludge, first fed into the Flow Control Tank, flows into the Flocculation Tank where polymer coagulant is added. From there, the flocculated sludge overflows into the dewatering drumwhere it is filtered and compressed. The entire operation sequence, including sludge feedcontrol, polymer makeup, dosing and sludge cake discharging, is controlled by the built-in-timer and sensors of the Control Panel.

Product detail pictures:

Related Product Guide:

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Wholesale Dealers of Screw Press Palm Oil Mill - Screw Press sludge dewatering machine – Haibar , The product will supply to all over the world, such as: Manchester, Sweden, San Francisco, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!