Short Lead Time for Ultraviolet Water Treatment - Dissolved Air Flotation (DAF) Thickener – Haibar

Short Lead Time for Ultraviolet Water Treatment - Dissolved Air Flotation (DAF) Thickener – Haibar Detail:

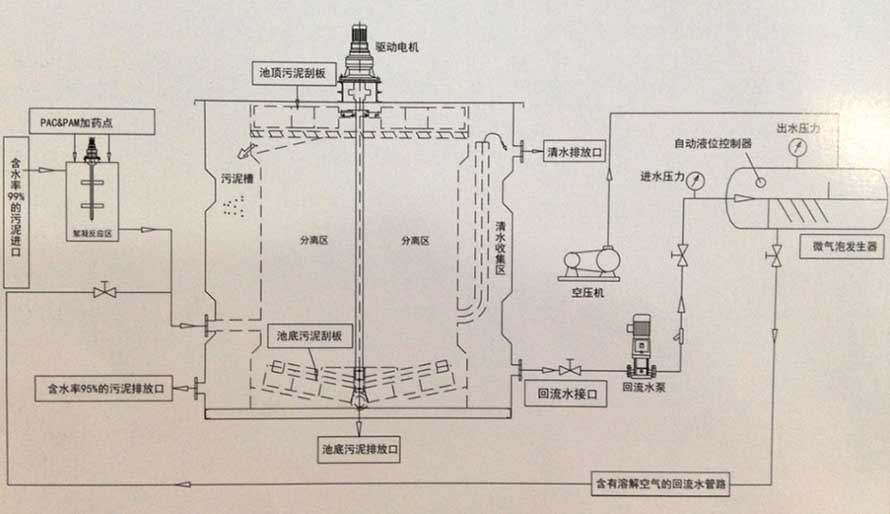

Structure and Working Principle

The residual activated sludge of a 98- 99.8% moisture content, micro bubbles and reagents are mixed in a flocculation reactor, which forms bubble flocs and then sends them through a mixing chamber, where they coagulate and grow larger. The sludge containing bubble flocs floats and gathers in sludge concentration zones and then separate from clean water using a buoyancy and sludge fence components. The moisture content in the sludge is gradually reduced, and the sludge gradually becomes dryer. Water extruded from the sludge is collected and discharged through a recycling water pipe in the middle of the pool body.

Product detail pictures:

Related Product Guide:

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for Short Lead Time for Ultraviolet Water Treatment - Dissolved Air Flotation (DAF) Thickener – Haibar , The product will supply to all over the world, such as: United Arab emirates, Ukraine, Montpellier, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Inquiry

Write your message here and send it to us