In sludge treatment, flocculation is the essential prerequisite for all mechanical dewatering equipment to operate efficiently.

Whether using a belt filter press, drum thickener, screw press, centrifuge or an integrated dewatering system, sludge must undergo sufficient flocculation before entering the equipment, forming stable and well-structured flocs.

Only when this critical step is completed can the dewatering system deliver its intended performance, achieving higher throughput, lower moisture content of dewatered sludge, and lower operating costs.

1. Why Is Flocculation So Important?

Flocculation is not a specific chemical but a pretreatment process before solid-liquid separation.

Its purpose is to allow fine particles in the sludge to aggregate into larger and more compact flocs through chemical reactions, so that they:

• Can be denser and more readily dewaterable by gravity or pressure

• Do not remain too fine and escape with the water flow

In short: without stable flocs, there can be no efficient dewatering.

2. What Problems Does Poor Flocculation Cause?

When flocculation is insufficient, the following issues are likely to occur during dewatering:

Low solids content and high moisture in sludge cake:

Loose floc structures reduce the equipment’s ability to apply pressure, making water removal difficult.

Increased chemical consumption and higher operating costs:

When flocculation performs poorly, operators often increase dosing, yet the dewatering performance remains limited.

Sludge carry-over, floc breakup and turbid filtrate:

Fine particles wash out with the filtrate, making it cloudy and potentially causing blockages or wear inside the equipment.

Reduced equipment efficiency or unstable operation:

Unstable flocculation can trigger chain reactions throughout the process, lowering the reliability of the whole system.

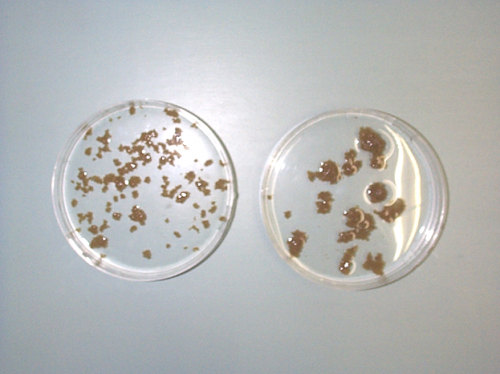

Performing a flocculation test

The flocculation result on the right is superior.

3. How Does Good Flocculation Improve Equipment Performance?

Higher solids content:

Denser flocs allow water to be expelled more easily by pressure, gravity or shear forces.

More stable throughput:

Well-formed flocs remain intact during operation, can withstand higher pressure, and help maintain consistent processing capacity.

Lower operating costs:

Effective flocculation reduces chemical dosage, minimises filter belt washing, and decreases mechanical wear.

Clearer filtrate:

Particles do not escape with the water, producing clearer filtrate that benefits downstream treatment and compliance.

4. Strong Synergy Between Haibar Equipment and Flocculation Processes

Over the past two decades, Haibar has specialised in the research and manufacturing of sludge thickening and dewatering equipment, including:

• Belt-type sludge thickener

• Drum-type sludge thickener

• Integrated thickening and dewatering unit

• Belt filter press, screw press and other solid-liquid separation systems

In all these applications, proper flocculation is the foundation of high-efficiency operation.

Therefore, although we do not sell flocculants, we provide full technical support during projects, including:

• Assisting customers with pilot tests to determine optimal flocculation conditions, such as dosing point, mixing time and dosage assessment

• Providing system design for dosing, mixing and chemical preparation equipment compatible with our machines

• Offering professional recommendations based on the characteristics of on-site sludge

Through comprehensive process guidance and well-matched equipment solutions, we aim to help customers achieve stable, controllable and efficient flocculation before the sludge enters the dewatering system.

Post time: Nov-24-2025