Leading Manufacturer for Continuous Sedimentation Tank - Dissolved Air Flotation (DAF) Thickener – Haibar

Leading Manufacturer for Continuous Sedimentation Tank - Dissolved Air Flotation (DAF) Thickener – Haibar Detail:

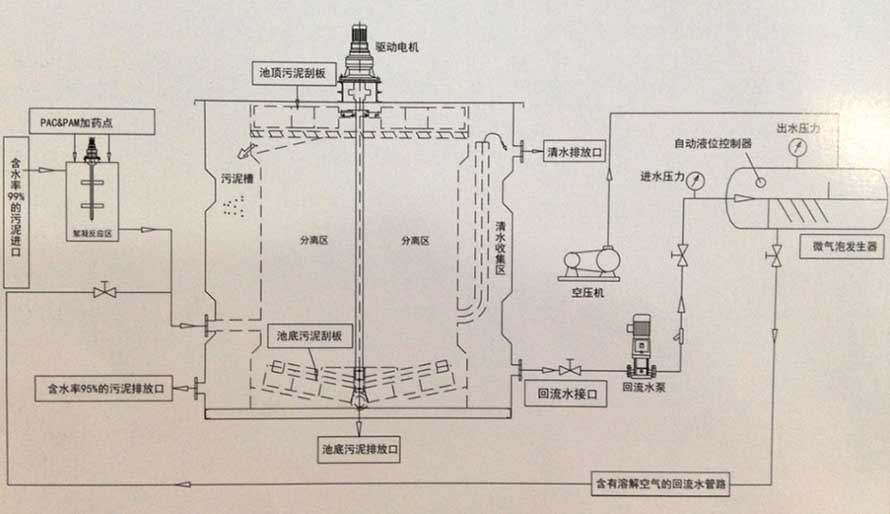

Structure and Working Principle

The residual activated sludge of a 98- 99.8% moisture content, micro bubbles and reagents are mixed in a flocculation reactor, which forms bubble flocs and then sends them through a mixing chamber, where they coagulate and grow larger. The sludge containing bubble flocs floats and gathers in sludge concentration zones and then separate from clean water using a buoyancy and sludge fence components. The moisture content in the sludge is gradually reduced, and the sludge gradually becomes dryer. Water extruded from the sludge is collected and discharged through a recycling water pipe in the middle of the pool body.

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for Leading Manufacturer for Continuous Sedimentation Tank - Dissolved Air Flotation (DAF) Thickener – Haibar , The product will supply to all over the world, such as: Israel, Malaysia, Somalia, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

Inquiry

Write your message here and send it to us