High definition Industrial Screw Press - Screw Press sludge dewatering machine – Haibar

High definition Industrial Screw Press - Screw Press sludge dewatering machine – Haibar Detail:

Mechanical Principle

The initial section of dewatering drum is Thickening Zone where the solids-liquid separating process takes place and where the filtrate will be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, increasing the internal pressure of the drum. At the end, End Plate further increases the pressure so as to discharge dry sludge cake.

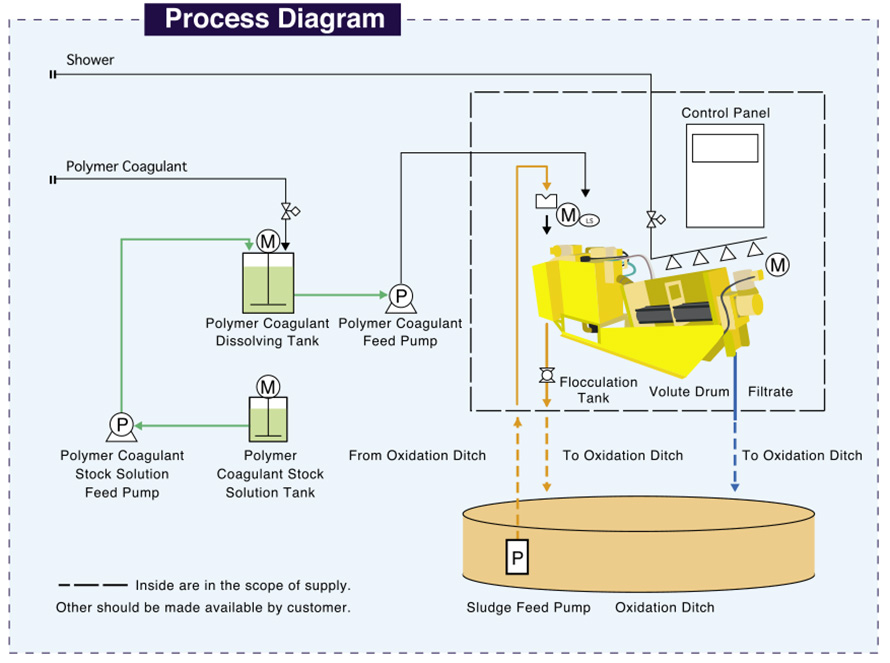

Process Diagram of the Vloute Dewatering Press

Sludge, first fed into the Flow Control Tank, flows into the Flocculation Tank where polymer coagulant is added. From there, the flocculated sludge overflows into the dewatering drumwhere it is filtered and compressed. The entire operation sequence, including sludge feedcontrol, polymer makeup, dosing and sludge cake discharging, is controlled by the built-in-timer and sensors of the Control Panel.

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for High definition Industrial Screw Press - Screw Press sludge dewatering machine – Haibar , The product will supply to all over the world, such as: Monaco, Honduras, Cancun, Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.