Good quality Juice Thickener - Gravity Belt Thickener – Haibar

Good quality Juice Thickener - Gravity Belt Thickener – Haibar Detail:

Features

Suitable for a variety of sludge types, even when the moisture content within the sludge is 99.6%.

Greater than 96% solid recovery rate.

Steady operation with little to no noise.

Easy operation and maintenance ensures the long service life.

The sludge thickener perfects the thickening process even when the sludge concentration varies.

There is a 40% larger output capacity than other machines that occupy the same amount of floor space.

Costs for land, construction, operation and labor are lowered due to the smaller space occupation, simple structure, less flocculants required and fully automatic operation.

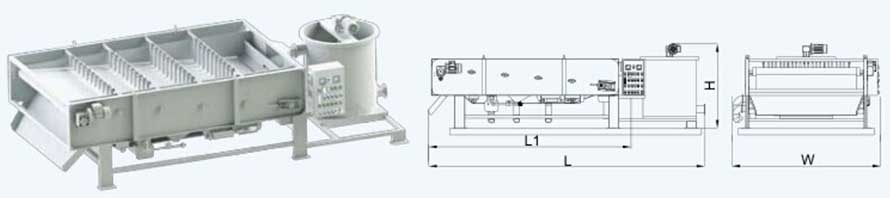

Components

Our gravity belt sludge thickener comes with superior quality gearmotor, rollers, filtering belt, and robust construction. It is also installed with stainless steel nozzles to clean the belt during operation, which can guarantee the continual performance of the belt thickener. The belt is aligned by the air cylinders automatically during the operation. It is tensioned either by mechanical springs with low investment, or by air cylinders for automatic operation.

Working Principle

The gravity belt sludge thickener depends on the gravity force to remove water from the sludge through a single woven cloth belt. Firstly, the slurry and flocculating polymer are evenly mixed in the conditioning tank. They become solid floc granules that can be easily dewatered after agitation. Then, they flow into the gravity drainage zone.

The flocculated sludge is uniformly distributed on the filtering belt. During the operating of belt, free water is removed from sludge by gravity through a fine mesh of the filtering belt. During the moving of sludge, special plows continuously turn and distribute the sludge across the width of the belt. The residual free water is further eliminated to achieve the sludge thickening process. In this way, the gravity belt sludge thickener allows both processing time and water content rate to be greatly reduced.

After filtration, the solids content of free water ranges from 0.5‰ to 1‰, which is closely related with the types and dosage of the polymer purchased.

Product detail pictures:

Related Product Guide:

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for Good quality Juice Thickener - Gravity Belt Thickener – Haibar , The product will supply to all over the world, such as: Latvia, Turin, Turin, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!