2020 Latest Design Filter Press For Sludge Dewatering - Screw Press sludge dewatering machine – Haibar

2020 Latest Design Filter Press For Sludge Dewatering - Screw Press sludge dewatering machine – Haibar Detail:

Mechanical Principle

The initial section of dewatering drum is Thickening Zone where the solids-liquid separating process takes place and where the filtrate will be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, increasing the internal pressure of the drum. At the end, End Plate further increases the pressure so as to discharge dry sludge cake.

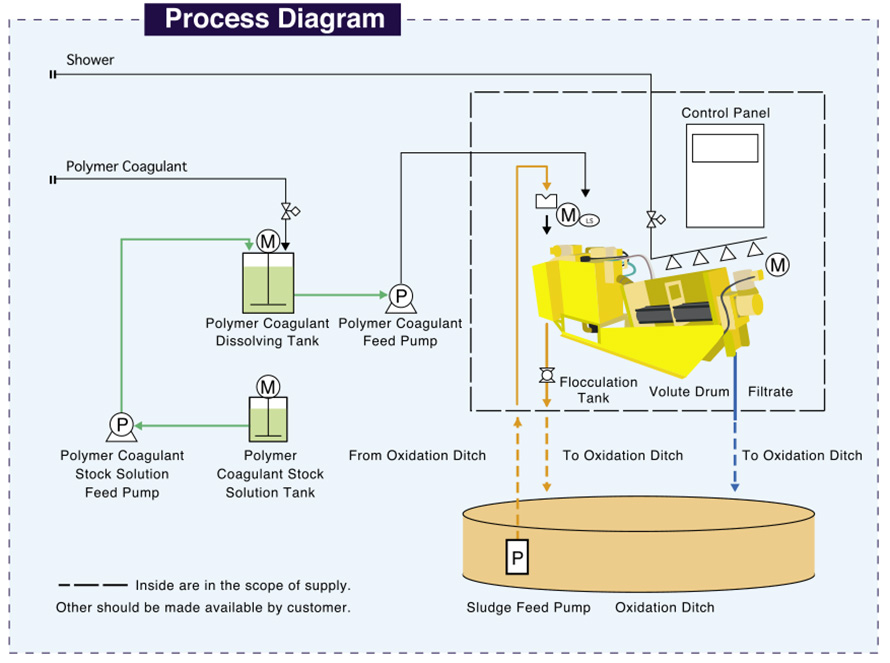

Process Diagram of the Vloute Dewatering Press

Sludge, first fed into the Flow Control Tank, flows into the Flocculation Tank where polymer coagulant is added. From there, the flocculated sludge overflows into the dewatering drumwhere it is filtered and compressed. The entire operation sequence, including sludge feedcontrol, polymer makeup, dosing and sludge cake discharging, is controlled by the built-in-timer and sensors of the Control Panel.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of 2020 Latest Design Filter Press For Sludge Dewatering - Screw Press sludge dewatering machine – Haibar , The product will supply to all over the world, such as: Bahrain, Ecuador, Ukraine, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.